Innovations Shaping the Future of Construction

The construction industry is undergoing a transformation, driven by ground-breaking innovations in construction practices. With the advancement of technology and a growing emphasis on sustainability, these new methods are not only changing the way we build but also shaping the future of our urban landscapes. This blog post delves into some of the most innovative construction techniques that are currently making waves in the industry.

Green Building Techniques

Green building, also known as sustainable construction, emphasizes environmentally responsible and resource-efficient processes throughout a building’s life cycle. From scoping through to design, then construction, operation and maintenance, and right through to eventual demolition. These changes are driven by the need to mitigate the impacts of climate change, conserve natural resources, and create healthier, more sustainable communities. These changes are being affected through both material science, improvements in construction methods and technological innovations.

Developments in Sustainable and Recycled Materials

Identifying and developing renewable and low-carbon processes is critical for the reducing the carbon footprint of common building materials. Improvements in our approach to material science and selection practices gives hope that the industry will achieve its decarbonisation goals.

Timber

Bamboo is increasingly being considered as viable composite construction material, particularly in developing economies. It is extremely fast growing, reaching maturity for construction purposes within 3 to 6 years. Bamboo fibres have a high compressive strength, comparable with concrete, and a tensile strength equal to mild steel. Greater adoption of bamboo in construction will reduce the demand on old growth forests and maintain biodiversity.

Credit: https://mastercivilengineer.com/application-of-bamboo-for-construction-and-architecture/

Steel

Steel production and recycling is increasingly efficient. Energy demands for production now 40% of the requirements in 1960. Notably, Material efficiency is approaching 100% (or zero-waste) with 97% of raw material converted into by-products or recycled. Additionally, Recycling rates in Australia stand at 97% for structural steel and 83% for scrap steel. Saving 1400 kg of iron ore, 740 kg of coal and 120 kg of limestone per tonne of steel recycled. (Steel Data).

Concrete

Concrete is a major contributor to the carbon footprint of buildings and infrastructure. Currently, the use of substitute cementitious materials (SCMs) such as slag (a by-product of steel production) and fly ash (a by-product of coal fired power plants) do reduce emissions. However, material science cannot yet eliminate the use Portland cement entirely, being the main contributor to concrete greenhouse gas footprint. Promisingly, there is enormous focus on finding suitable substitutes to Portland cement, with 25,000 research papers on SCMs published since 2010. (Future and emerging supplementary cementitious materials – ScienceDirect)

Technological Innovations in Green Construction

Technology is playing a pivotal role in the advancement of green building techniques. Improving design software, renewable energy products and data analytics are making our buildings and infrastructure increasingly energy efficient.

The sophisticated digital tools at our disposal, such as Building Information Modelling (BIM) allows for more precise and efficient planning, reducing waste during construction. Advances in design software also enable architects to simulate energy efficiency allow for changes in building materials, form and orientation to optimise passive solar gain and natural ventilation during operation.

Continuing advances in solar technology with products such as photovoltaic glass and solar shingles promise to turn entire building envelopes into renewable energy sources. This will dramatically increase on site power generation and reduce the need for energy from the grid.

The integration of sensors within materials and structures will allow for the collection of data in real-time. This data will be used to monitor structural health, optimise energy consumption, and control indoor environmental conditions. Resulting in buildings that can react and adapt to their surroundings. This will not only improve the lifespan and performance of the structure but also enhances the inhabitant’s experience by creating interactive and adaptive spaces.

Prefabrication and Modular Construction

Prefabrication methods have indeed come a long way from precast concrete elements. Today, we see entire building sections produced off-site in a factory-controlled environment. This continued shift toward advanced prefabrication and modular construction will transform the industry with streamlined processes, reduced costs, and enhanced quality. Fabrication in controlled factories eliminates weather delays, ensures components are produced with precision, and significantly reduces material waste.

Design for Manufactured Assembly with BIM

Building Information Modelling (BIM) supports meticulous planning and visualisation of every component during design. This technology enables precise manufacturing of complex, custom elements that fit seamlessly when assembled on-site, and crucially reduces the need for adjustments and rework. Additionally, new materials and methods, including 3D printing and high-strength, lightweight composites, are expanding the possibilities of what can be prefabricated.

Improvements in Transportation and On-site Logistics

Logistics and transportation of prefabricated modules have become more efficient too. With the development of specialised equipment and methods to move large and complex structures safely from the factory to the construction site. Once on-site, the integration of prefabricated modules with existing building systems has become more seamless, thanks to BIM enabled design coordination and connection technology, ensuring that the assembly process is swift and secure.

Advanced Materials and Smart Technologies

The construction industry is embracing innovative advances in material science. These innovations promise to enhance the efficiency, sustainability, and resilience of construction projects. These innovative materials include:

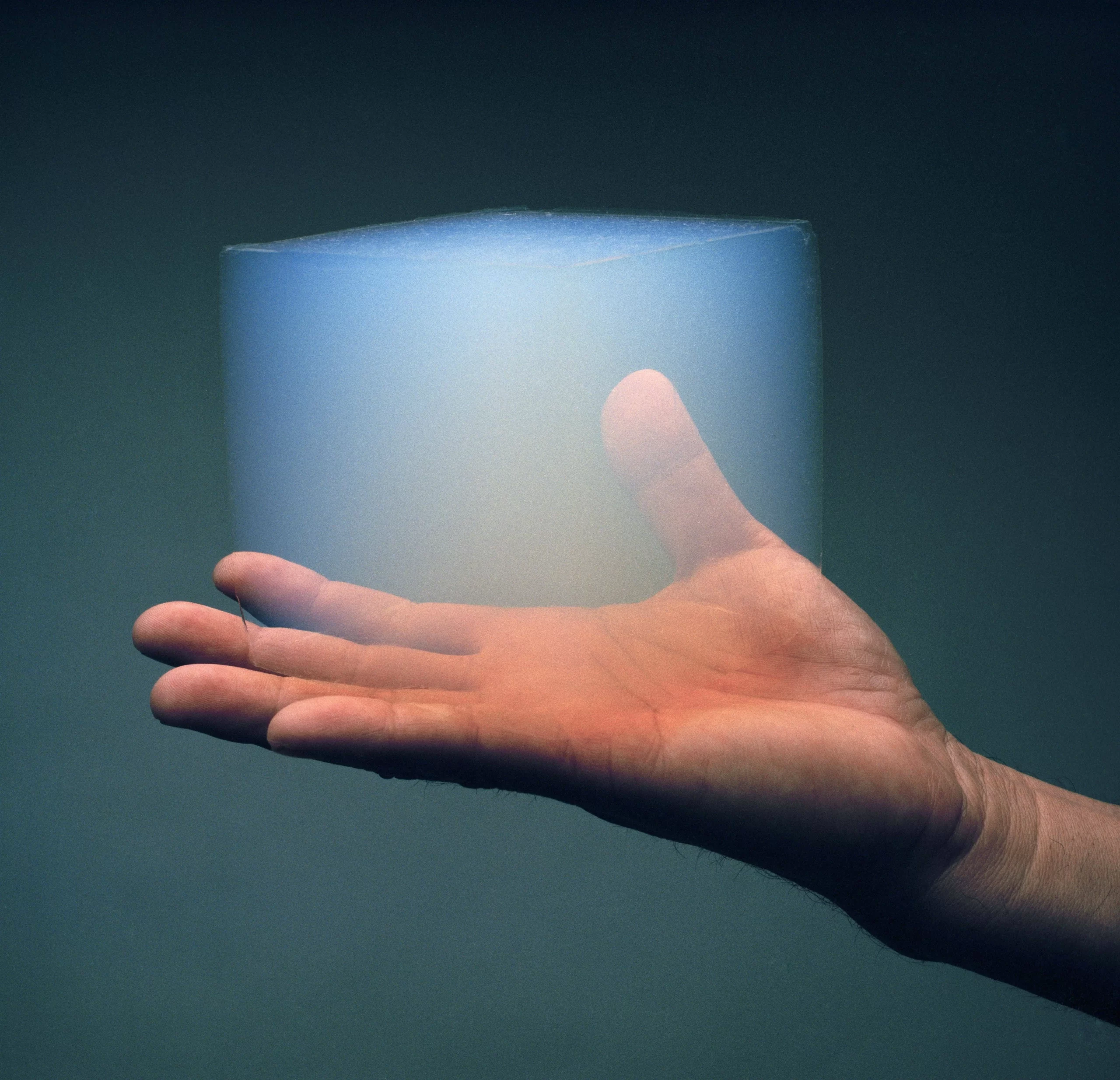

- Self-healing concrete, which can repair its own cracks;

- Lightweight, yet strong, aerogels for insulation; and

- Translucent wood that allows for natural lighting while maintaining privacy.

These examples show just how material science is pushing the boundaries of what’s possible in construction.

The Role of AI in Material Innovation

Artificial Intelligence (AI) is playing an increasingly significant role in the development of new construction materials. AI algorithms can analyse vast amounts of data to predict material behaviours and properties, enabling the design of materials with tailored characteristics. AI can rapidly devise and test new material compositions, significantly shortening the development cycle and accelerating the pace of innovation. This will lead to breakthroughs in material science at a bewildering pace, further enhancing the quality and capabilities of our buildings and infrastructure.

Conclusion

Innovative construction methods such as green building techniques, prefabrication, and the integration of advanced materials are not only revolutionising the way we build but also redefining our expectations of the built environment. The construction industry, by integrating these innovations, is set to offer structures that are not only built faster and at a lower cost but also with greater attention to sustainability and precision. The future is bright, and as these practices become increasingly mainstream, they promise to deliver a blend of ecological, economic, and social benefits, cementing a sustainable blueprint for construction and project management for years to come.

What innovative approaches are you using on your construction projects? We would love to hear about your experiences. If you would like a deeper conversation on how innovative construction methods can transform your projects get in touch.